i4F is exhibited Click For You at DOMOTEX 2023 – The World of Flooring.

Hello my name is John Rietveldt and I am the founder and CEO of i4F.

i4F is an innovation company in patterns and technologies, mostly focused on the flooring industry.

i4F is an innovation company in patterns and technologies, mostly focused on the flooring industry.

And we’re happy to present here at Domotex here in Hanover.

Some of our big Innovations we are bringing currently to the market and which we have brought over the last couple of years.

As i4f, our core competence is around locking and we have changed the flooring market over the last years, to bring the whole market to an easy installation system.

And easy installation locking.

And it works like that.

And it works like that.

You have your panel on the ground, you put the following panel in and then the panel next to that you drop in and you click it.

So it’s a very easy installation you do it vertically.

And once you want to take that out, once it is not good installed or whatever, it’s very easy.

And once you want to take that out, once it is not good installed or whatever, it’s very easy.

You slide it out of each other and you can redo it.

So this is a very important innovation.

It’s called “Click For You”.

And it is used almost by every manufacturer in the world so you will find it in all retail stores.

It’s called “Click For You”.

And it is used almost by every manufacturer in the world so you will find it in all retail stores.

And we really want to help the market to to accelerate the growth by giving it easy installation.

So it’s not only good for consumers who can do it themselves but also for professional installers who normally are paid by square meter or square feet.

And they can do many more square meters and square feet.

We think 30 percent more in the same time.

We think 30 percent more in the same time.

So, a very important innovation.

So, another Innovation I would like to introduce to you is the grout technology and what it basically does.

So, another Innovation I would like to introduce to you is the grout technology and what it basically does.

It is an SPC panel.

So a “solid polymer core” with an additional layer underneath the decor layer which create after the profiling of the locking, a certain look.

So a “solid polymer core” with an additional layer underneath the decor layer which create after the profiling of the locking, a certain look.

And we call that the grout look.

It’s a complete one-to-one imitation of a ceramic tiles so that allows people to replace ceramic tiles in the future by a modular products which easily can be taken out also in the future, which is much more easier than tiles, ceramic tiles.

It’s a complete one-to-one imitation of a ceramic tiles so that allows people to replace ceramic tiles in the future by a modular products which easily can be taken out also in the future, which is much more easier than tiles, ceramic tiles.

We have that in… of course with different colors the customers and the manufacturers can choose what kind of color they would like to have as their grout.

So very important innovation with… people like a lot.

So to the next Innovation I would bring you.

As i4f, we are very much focused on sustainable solutions for the future Innovations which will change the world over time.

As i4f, we are very much focused on sustainable solutions for the future Innovations which will change the world over time.

One of the key elements is around material savings we have introduced the technology that is called “B light”.

And the “B light” basically takes materials out of the backing of a panel of SPC.

And the good thing of this is that there will be less material coming out of the extruder and through a cylinder the shape is pushed into the backing which makes them a thicker board.

This is a strong saving which can go up to around 20 percent in weight.

This has another advantage because logistic costs are based on container prices in most of the occasions and

through this weight reduction you can have more square feet or square meter in the same container.

So you’re not only reducing the material cost and the material usage but also the supply chain cost.

So you’re not only reducing the material cost and the material usage but also the supply chain cost.

And last but not least for installers or consumers you create a lighter board.

So at the end to buy and to carry a couple of packages, it will be less intensive as it is now.

So at the end to buy and to carry a couple of packages, it will be less intensive as it is now.

So it’s extremely important innovation.

It’s called “B light” and we have very high expectation that the industry will adopt this and will carry this out to to the marketplace.

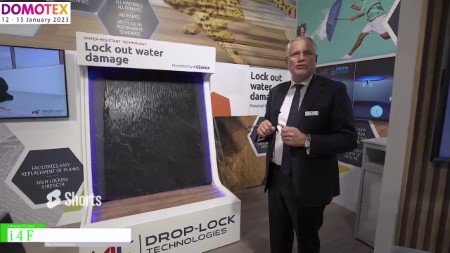

Within our locking family we have developed a specific locking for laminate which is fully water resistant because of the sensitivity of the material, the HDF.

If it gets in contact with water it has the potential to swell.

So the first thing you need to address is to make the locking water tight.

So the first thing you need to address is to make the locking water tight.

And you see here an example, these are real boards where you see that no water is penetrating in any of those joints and locking.

But that as such is not enough you could always have some contact on the top with water.

And for that we have developed a technology which is called Aqua Protect.

And it is an impregnation of your HDF board where the locking is based to make the HDF completely water resistant so that you don’t swell the MDF when you bring it in contact with water.

So the combination of “I click for you”, the locking which is water tight and “Aqua Protect” which is a impregnation for the HDF board makes a superb board for the laminate industry.

And allows to bring it in contact with water both to clean or if there is more volume of water on the boards.

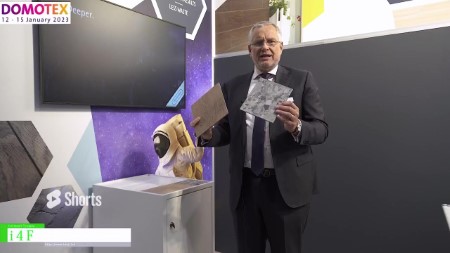

So last but not least we show here the last Innovation for the ones we have chosen to present at this exhibition.

And this is all about digital printing.

So what it means is you have an SPC board and you print directly on the board.

So with that you can create an enormous amount of different designs and a very specific articulation of certain designs.

You see here a certain stone look but you could also have that on the traditional wood look.

So you don’t have any layer anymore you print exactly what you would like to print.

So that… as an advantage that there is much more choice for the customer and at the same time that he can have the product quicker.

But the only thing what needs to be done is to program the design and get the products produced.

And for the industry it has a big advantage that ultimately you don’t need to have so much inventory because since you produce what the customer would like to receive,

you don’t need all the volume of inventory in the warehouse.

So this is really a win-win.

There’s less money invested and much more choice for the end consumer.

We believe that digital printing will be a huge transition in the flooring market.

We believe that digital printing will be a huge transition in the flooring market.

Recently several people have bought digital printing lines and signed up for the technology and we think that that will be one of the main topics of the exhibitions which will come in the next couple of years.

So very excited about that. It’s a big big change in the market.

So, of course after what you have seen and heard, you would like to have more information I would like to refer you to our website www.i4f.com/

So, i4f.com you will find more exciting Innovations than you have seen now but for sure also the ones you just have seen. So thank you very much.