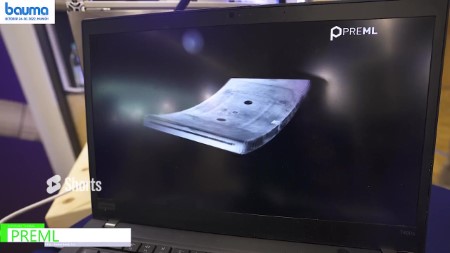

Automatic visual quality inspection is exhibited PREML at bauma 2022.

So hi. I’m Jonas, one of the co-founder from PREML, and we are basically a startup from Germany.

and we are doing automatic visual quality inspection.

and we are doing automatic visual quality inspection.

So we are checking some parts like, for example, precast industry,

we are checking the surface for defects for example spellings or cracks or also of any missing building parts are there on the part.

And yeah basically we are doing all kind of image processing, independent from the materials.

So we also check like metal, wood or plastic.

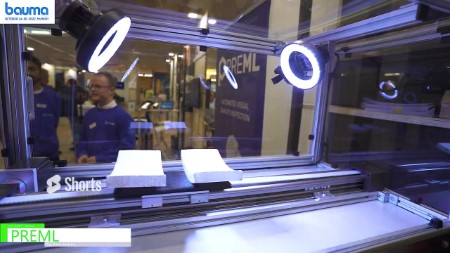

here we see a miniature version of our real case.

here we see a miniature version of our real case.

In the real world, they are much bigger like two by four meters.

And we are detecting the cracks on the five sides, five visible sides and this all happens inside the TPM.

And we are detecting the cracks on the five sides, five visible sides and this all happens inside the TPM.

So the part is coming in then we detect the position of this part.

and if it’s at the correct position we take snapshots from each side,

then you use a CRD model to fit the contours on the part and rectify the images doing some pre-processing steps.

then you use a CRD model to fit the contours on the part and rectify the images doing some pre-processing steps.

and afterwards we train the artificial intelligence to detect like cracks, spoilings or any missing building parts.

And this will be shown to the operator on our dashboard where I can also monitor the process at each time.

and we will decide if the part is good enough, if it needs to be repaired.

If you have any task or use case for a visual inspection then you can contact us on our website www.preml.io/ And thank you.