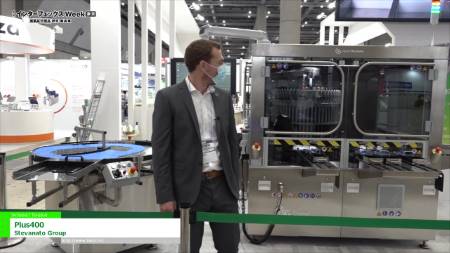

Stevanato Group is exhibited “Plus400” ampoule, vial and cartridge inspection system at 24th INTERPHEX Week 2022.

website:https://www.stevanatogroup.com/

Hello everybody. This is our inspection machine, produced by Stevanato Group. It’s our top model.

Maximum piece is 400 pieces per minute and it’s also the most flexible machine that we can have.

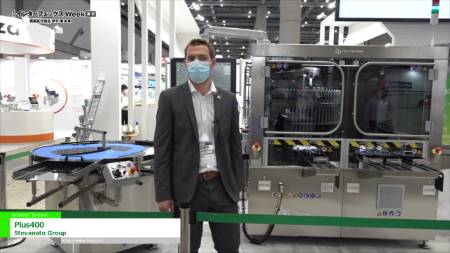

It can inspect the container sign two hard dimension up to 20 hard for vials, also imports from one ML up to 10 ML.

And also cartridges.

Not only liquid, but also layer product.

Not only liquid, but also layer product.

So this machine can just change the performer parts and load the different recipe that has different parameterization.

It can inspect all this kind of product.

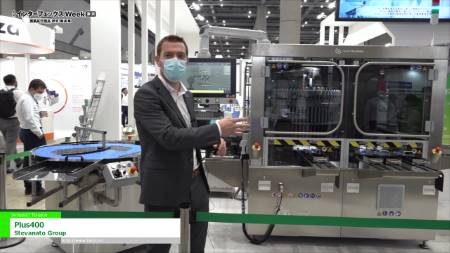

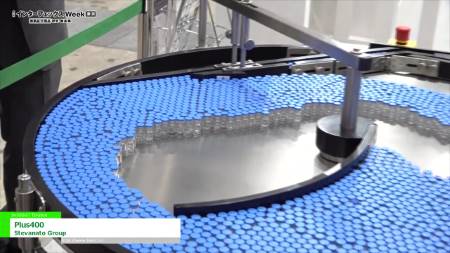

In fact, it has a big turret where we can look.

While I’ve located the most of the inspection station.

This machine can have up to 20 cameras for the inspection station.

While I’ve located the most of the inspection station.

This machine can have up to 20 cameras for the inspection station.

Each camera can take, for particle inspection, up to 60 frames for each container.

A base configuration can be three, four particle inspection stations, one cosmetic for the inspection for the body,

one cosmetic station for the hollow ceiling inspection.

Other station dedicated for to check the flip off stopper presence.

Color of flip off, outside the turret.

Color of flip off, outside the turret.

Other inspection outside the turret can be the bottom inspection.

And other inspection can be applied according with the customer request.

For what I can see, this is a compact also machine.

Also, having this kind of inspection and extra model can be added, if for example, leak detention, is another requirement from the customer.

In feed, out feed, also this part of the machine can be customized.

That case for vial is more indicated the rotating table,

but also in feed belt can be out of the machine for impulse inspection, cartridges inspection.

but also in feed belt can be out of the machine for impulse inspection, cartridges inspection.

The same for the out feeder. Can be in line.

So we can have an out feed belt for the asset items or trays according with the customer.

Reject trays are more than one just to collect the different rejects and different trays.

Also, that case we have four reject trays, one for flip off defects, one for particle defect, another for field level defects, and the other for cosmetic defects.

Extra trays can be added according with customer request, obviously.