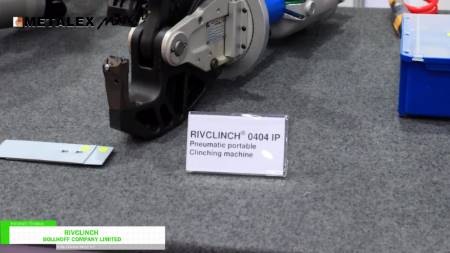

Bollhoff Company Limited is exhibited RIVCLINCH at METALEX March 2022.

Hello, I’m from Bollhoff Thailand, selling fastener from Germany.

In the event, we will have all three Highlights.

In the event, we will have all three Highlights.

There will be in the Rivet Nut part, which is the female nut work.

In Japan it’s called Pop Nut, in Europe it’s called Rivet Nut.

It’s the creation of a thread in a metal sheet by using this Rivet Nut that has a thread inside.

It’s the creation of a thread in a metal sheet by using this Rivet Nut that has a thread inside.

Embedded into the workpiece by using the machine to install into it.

I’ll show you a demonstration.

Put this screw in.

Let’s say this is a customer’s work piece. Then press and hold.

Then we will be able to create threads in sheet metal.

Then we will be able to create threads in sheet metal.

Suitable for metal work, metal sheet work, furniture work. control cabinet and car work.

Which we will support the whole child and the machine

Which the machine will be available in 2 models, P2700 and P2500, depending on the needs of the customer, which size to assemble.

And in the Rivet Nut section, we also have a choice of hexagonal.

Or in a circle, there are steel, stainless steel and aluminum.

The next product will be Rivet Nut, a general Rivet, used for general work,

including Normal Rivet and Construction.

Rivet.

This is this one.

Rivet.

This is this one.

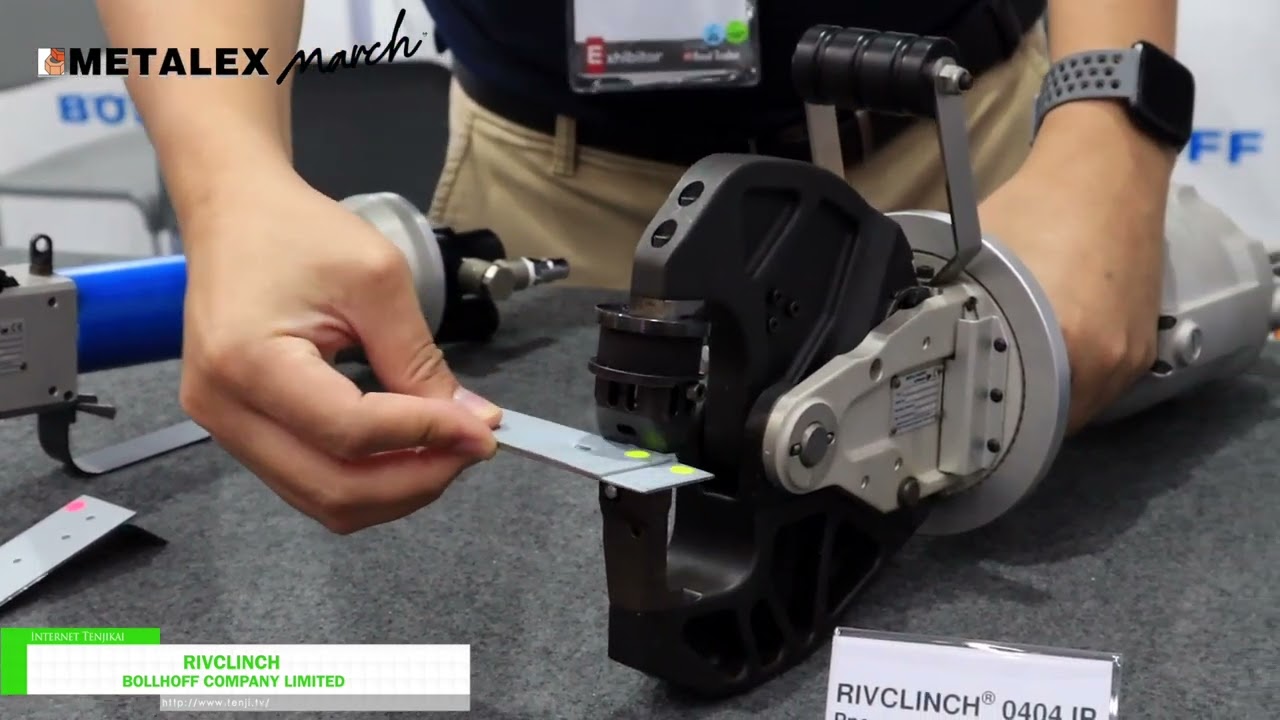

Clinching technology is used instead of Spot Welding.

Of course, Spot Welding customers know that able to weld only materials of the same type.

Such as steel with steel or stainless steel with stainless steel,

Such as steel with steel or stainless steel with stainless steel,

which will have limitations on of causing the workpiece to be heated.

Ours destroyed that wall.

Where the customer is able to weld metal by “reertching” or in English called Clinching,

Where the customer is able to weld metal by “reertching” or in English called Clinching,

which the customer will be able to combine the material between steel and stainless steel or steel and aluminum without limitation.

Importantly, in the event that the customer has an insulator in the middle separated, it can be welded.

If it is a general spot welding, it will not be able to weld.

This one is easy to use.

This one is easy to use.

You don’t have to drill holes first.

By using our “repeat” machine, which will have a variety of models. but in our work We will show it as an initial model.

By using our “repeat” machine, which will have a variety of models. but in our work We will show it as an initial model.

Here, just take the work. An example would be two sheets.

Put the workpiece in and press it, the machine will be able to weld it.

which the welding force It is as strong as Spot Welding

and does not cause burns in the workpiece.

and customers do not have to finish the new job.

and customers do not have to finish the new job.

Ask for more information with our company.

which we will have both a demo and have a team to support

which we will have both a demo and have a team to support

In the event that customers have additional questions about our products.

We are happy to support and customer service in the next opportunity

We are happy to support and customer service in the next opportunity